The ACE 3000 was a prototype modern 4-8-2 coal-burning steam locomotive which was designed in the late 1970's to early '80's by Ross Rowland, L. D. Porta, and a design team from the American Coal Enterprises company.

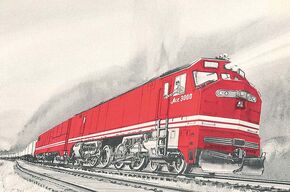

An artist's rendering of the early ACE 3000 design.

The purpose of this project was to offer railroads an alternative fuel to the steeply increasing cost of diesel fuel.

Although it was proposed to several railroads, major construction never began. After public interest died, the project was cancelled and dropped by ACE. Several factors led to this cancellation, including general disinterest, small driving wheels, and EPA's claims of environmental danger (which were completely unfounded and based only off the visible smoke which typically emits from steam locomotives).

Design

The ACE 3000 was designed to visually resemble a diesel locomotive with the then-new "Canadian Comfort Cab," recently designed by the Canadian National Railroad in cooperation with EMD. It was to be equipped with a duplex-drive non-articulated 4-8-2 steam locomotive chassis with 2 cylinders on either side, a cab-forward configuration boiler with belpaire firebox, Walschaerts valve gear, and a central crankshaft to synchronize the operation of the high and low pressure cylinders. It was also designed to be operationally similar to diesel locomotives by using a computer microprocessor to control and monitor fire stoking and water usage and an 8-notch throttle. It was to be operated by one man, the engineer, who could also MU the unit with other ACE units as well as diesels, and could keep itself prepared while idling. Conventional steam locomotives, by contrast, required constant attention from at least one fireman to keep the steam, fire, and water all balanced to prevent a boiler explosion. Boiler Pressure was rated at 300 psi with fire-tube arrangement and superheater. Drivers are a mere 54 inches, though ACE justified this by claiming the drives were kept small so that the railroads could easily maintain them in the same facilities they maintain diesels in. Low drivers meant a low chassis similar to diesels sizes of the time. Despite the driver's small size, they were to be capable of 70 mph maximum speed, although the locomotive was designed to operate most efficiently around 40-50 mph, a speed typical of most trains of the time. The Power Unit (ACE for locomotive) was also equipped with a condensing system which would first reduce it to high temperature water and then cool this in the tender. That was said to negate the difficulties had by the condensing systems on South African locomotives designed by L. D. Porta's earlier endeavours. Since the steam is now in a looped-condensing system, a turbine-driven fan was added to draught the fire, which, incidentally, would have eliminated the "chuffing" sound steam locomotives were know for.

Maintenance

The small drivers were only a part of the locomotive's design effort to be very easily maintained and handled. Although the engine was to be shrouded in a cowl body which covered the boiler in a manner similar to streamlining, this cowl is easily removable and therefore should not cause hassles like other steam era designs. The cabs on both the power unit and support unit (the name given to the tender of the ACE 3000) were to be modularized, allowing easy removal and access to all inner parts and systems. The chassis was also designed to allow easy access to parts by keeping compact running gear and a low profile. The chassis was also equipped with built in pneumatic jack systems to eliminate the need for an overhead crane. Fueling was also greatly simplified. The Support Unit was to have 3 slots designed to fit "packets" of about 11 tons of coal each which would be loaded by crane and switched out once empty. The coal and water supply was good for about 500 miles at maximum power, which would be roughly the equivalent of 13 hours running time. Water towers would no longer be necessary because of the Support Unit's vastly improved capacity, which is helped by the condensing apparatus. Total water would be good for about 23 hours at optimum output. Another bonus from the improved range would be time to more thoroughly treat the water, which the design team claimed would bring the necessary boiler inspections down to one per year.

Trivia

- The Chessie System was originally interested in purchasing the locomotive, but it backed off after multiple design changes made the locomotive too different from American steam practice. It went as far as running lightly modified former Chesapeake And Ohio 4-8-4 "Greenbrier" 614 to collect fresh data on steam locomotive performance potential.

Sources

- Train Web.org - "The ACE 3000" pages 30-32, Railfan & Railroad November 1981.