This page is about a type of internal-combustion engine. For other uses, see Diesel engine (disambiguation).

This article or section may need to be rewritten, because it needs a technical review. You can help Locomotive Wiki by improving it!

Please remove this notice if the page has been edited majorly.

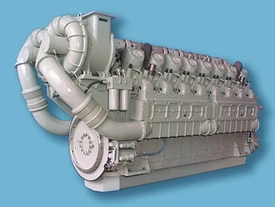

A modern diesel engine, the EMD 16-265H.

A cross-section of a John-Deere tractor engine. (6-cylinder; inline formation)

A diesel engine ("diesel motor" or "prime-mover") is an auto-ignition type of reciprocating internal-combustion engine. It was invented by Rudolf Diesel in 1897, hence the engine's name.

The engine is most useful in heavy-duty applications. It consumes diesel fuel (a petroleum distillate) and air to convert heat into energy thus propel: four-wheel drives (4x4s), trucks (lorries), farm-machinery, construction equipment, locomotives etc. The diesel engine has recently been adapted for use in small city-cars to make them more fuel efficient, and to help lower the overall fuel consumption/pollution figures of current car-makers' model ranges.

History[]

In 1206, an Arab inventor named Aljazari wrote Book of Knowledge of Ingenious Mechanical Devices that depicted the first known description of a crankshaft. Over 670-years later the crankshaft was first used to make the internal-combustion engine a commercial success.

A Swiss inventor, François Isaac de Rivaz, made the first working example of an internal-combustion engine in 1806. A hydrogen and oxygen mixture powered it, but despite François' hope that it would power a horseless-carriage, the device proved commercially unsuccessful.

In 1876 Dr. Nikolaus Otto, a German engineer, built the first four-stroke (four-cycle) engine, which ran on refined gasoline. Later, Dr. Rudolf Diesel, another German engineer, suggested that there was no need for the electronic ignition, used by Otto's engine, in Diesel's 1892 and 1893 patents. His solution was to build an engine that could compress air and fuel to the point of self-ignition. Originally Diesel was going to use powdered-coal to power his design, but an explosive — near fatal — set-back led him to use his fall-back fuel: gasoline (petroleum). Diesel built his first engine in 1897, which ran on "diesel fuel"; a less-refined form of gasoline (petroleum).

The first commercial use of Diesel's engine was by a brewer called Adolphus Busch, in Saint Louis, Missouri, USA. Busch had seen the engine at an exhibit in Munich, Germany, and paid Diesel for the design's manufacture and sale in the United States of America and Canada. The St. Louis engine was very reliable and ran for many years. It inspired the Busch-Sulzer engines that were used in U.S. built submarines during World War I.

Design and Operation[]

To achieve auto-ignition, an internal-combustion engine needs a compression-ratio at least that of 14:1, and most designs do not go higher than 22:1. This means that the air-fuel mixture has to be compressed to at least one fourteenth of its original size, and no more than one twenty-second.

Inside the engine-block, there are cylinders. These cylinders have a piston that reciprocates (moves up-and-down) inside the length of the cylinder. When the piston travels the length of the cylinder in one direction, this is called a "stroke". These cylinders are closed off at one end (which is called the cylinder's "head"), between this and the piston, which seals the other end of the cylinder, is called the "combustion-chamber". The piston's travel distance is controlled by a "connecting-rod" that joins the piston to the "crank-shaft". The crank-shaft itself, which is located in the "crank-case" (below the cylinder bank), is joined to all the connecting-rods of the engine, and leads the power to a "flywheel". This, flywheel, is then connected to the rest of the "drive-line" (or "drive-train"). The drive-line includes the engine, any form of: transmission, drive-shafts (power transmitters), differentials (power splitters; between axles, or wheels, for instance), axles and finally the wheels themselves. (Note that not all of these things are used on most diesel locomotives, since they tend to be mostly diesel-electric. This means that the flywheel would connect to a drive-shaft and then to an electricity-generator.)

Overview[]

The two-stroke diesel engine has one power-stroke per revolution of the engine's crank-shaft. The piston's first stroke (upward) lets the air into the combustion-chamber (via exposing a port in the cylinder's side), and then compresses the air (against the cylinder's head) until it's very hot. The piston's second stroke (downward) is started by the injection of fuel, which ignites immediately, pushing the piston down the cylinder (creating power), and releasing the exhaust gases through another port cast in the cylinder's side.

The four-stroke diesel engine has one power-stroke per two revolutions of the engine's crank-shaft. The piston's first stroke (downward) draws air into the cylinder by creating a partial-vacuum. The piston's second stroke (upward) compresses the air until it's very hot. The piston's third stroke (downward) is started by the injection of fuel, which immediately ignites, causing the piston to be forced down the cylinder (creating power). The piston's fourth stroke (upward) pushes the exhaust gases out of the combustion-chamber.

Two-stroke[]

The two-stroke (two-cycle) diesel engine is less complicated than the four-stroke version. For instance, it has no moving valves (tappets).

The first stroke starts when the piston exposes the (non-return) inlet port on the cylinder's side (when the piston "stops" on the cylinder's base), and the injection of compressed air into the cylinder's combustion-chamber commences. The air is injected only by the expansion of the compressed air itself. Once the piston starts moving back up the cylinder, towards the cylinder's head, it closes off the inlet port, stopping more air entering the combustion-chamber. The piston keeps moving up and therefore compressing the air in the combustion-chamber, eventually heating the air up. This is called the intake and compression stroke.

When the piston is at is upper-most, therefore the air is at its hottest, fuel is injected into the cylinder via the use of more compressed air, and the volatile mixture ignites starting the second stroke. This ignition is a violent, controlled burn throughout the combustion-chamber; the result of which is that the heat expands, forcing the piston back down, towards the cylinder's base. (The force, or power, is transmitted by the connecting-rod to the crank-shaft, which transmits it to the rest of the drive-line.) Just before the piston returns to the cylinder's base, it exposes the outlet port on the cylinder's side. (The outlet port is cast slightly higher than the inlet port.) This lets the exhaust gases, caused by the explosion, to start exiting the combustion-chamber. Some exhaust gases cannot leave the combustion-chamber once the pressure has dropped, this is solved when the inlet port is expose again; resulting in compressed-air blasting the cylinder "clean". This is called the power and exhaust stroke. Afterwards, the operation restarts with the intake and compression stroke.

This type of engine, the two-stroke diesel, is rarely used now. It was used after World War I, in peace-time applications, but to save money in construction and maintenance the design was modified. A notable modification was the addition of a 'pre-combustion' chamber. This chamber had a "glow" bulb, or tube, in it. The fuel passed through this chamber, and ignited, before entering the combustion-chamber. These engines are referred to as "semi-diesels", because they lacked the "magic" compression-ratio of, at least, 14:1 that is needed for auto-ignition.

Four-stroke[]

The four-stoke (four-cycle) diesel engine is much more efficient than the two-stroke, but is much more complicated as well.

The first stroke starts with the piston in the upper-most position (against the cylinder "head") and moves downward. As the piston moves down the cylinder, the inlet valve (tappet) near, or at, the cylinder head opens. The act of the piston retracting down the cylinder creates a partial-vacuum that draws air into the combustion-chamber (induction). Once the piston is at the cylinder's base the inlet valve has closed. This stroke is called the induction stroke.

The piston then moves back up the cylinder on the second stroke. This compresses the air causing it to heat up. When the piston is at its upper-most again, therefore the air is at its hottest, fuel is injected into the cylinder via the use of compressed-air. This stroke is called the compression stroke.

The volatile mixture then ignites starting the third stroke, due to the piston being forced down the cylinder by the expanding heat. The piston is pushed down to the cylinder's base transferring the force (power) to the crank-shaft, via the connecting-rod. This stroke is called the power stroke.

Once there, the piston leaves the cylinder's base and returns upwards on the forth stroke. This stroke pushes the exhaust gases, created by the combustion process, out of the outlet valve (which is opened with the upward movement of the piston.) This stroke is called the exhaust stroke. Afterwards, the operation restarts with the induction stroke.

In the four-stroke diesel engine, the "valves" (tappets) are different from the two-stroke engine's "ports" mainly due to them having moving parts. These moving parts, that resemble solid "trumpets", are pushed down (into the combustion-chamber) by a rather complicated mechanism. The pistons connect (via connecting-rods) to the crank-shaft in the crank-case. Also connected to the crank-shaft is a chain-drive mechanism that uses power from the pistons to turn a cog. This cog transversely operates (via "teeth") a "cam-shaft". The cam-shaft has "cams", or bumps, on it that push a rod upwards at timed intervals. This rod, aptly named the "push-rod", is connected to a "rocker" (see-saw; centrally pivoted beam), that acts upon the valves (tappets). The better the timing of the valve opening and closing is, the more power an engine can produce.

The four-stroke diesel engine also needs to be very well balanced. For instance, to keep an efficient inertia (continued, unpowered movement) when the cylinders are not firing, the engine uses a "flywheel". This flywheel is attached to one end of the crank-shaft, and rotates with it. The flywheel uses centrifugal force (the faster it spins the heavier its rim becomes) to even out the "beats" of the four-stroke cycle. This is due to there always being a minuscule delay between cylinders' compression-strokes. Therefore the engine would pulse on and off if the flywheel did not "blend" the transition between cylinders firing. The flywheel is especially useful in single cylinder layouts.

Engine Formations[]

There are several different engine-block formations for internal-combustion engines. These are the most common:

- The most basic is the inline (or straight) formation, where the cylinders are next to each other in a line. These types usually don't have more than six-cylinders, due to the length of the engine-block. This is a normal design used by diesel engines.

- The next most common configuration is the V-formation (or Vee-engine). In this type the cylinders are set in a V with the pistons working off the same crankshaft. The space between the cylinder banks is usually taken up by the fuel inlet manifold. These engines are space-efficient, so they can often be found in four- to twelve-cylinder guise — sometimes more. This is a normal design used by diesel engines.

- Another type of engine is the boxer (or flat engine) formation. This is very similar to the V-formation, only it lays the cylinder banks down; therefore half of the pistons move away from the other half, and back again. This formation does not normally go beyond six-cylinders. This is either a very rare design used by diesel engines, or it has never been used in that way.

References[]

- Encyclopædia: Britannica Deluxe Edition. 2010.

- Book: The Railway Data File published by Silverdale Books. ISBN: 1-85605-499-3.

- Encyclopædia: The World Book. p. 116–117. 1966.

- Encyclopædia: "The Internal Combustion Engine". Science. Published by Dorling Kindersley (2009). Editor-in-Chief: Adam Hart-Davis.